Following the resolution of issues raised by the first batch of user feedback, we embarked on preparing for the production of our second batch with great anticipation. This time, our plan was to fulfill the orders of all crowdfunding backers. Taking into account the crowdfunding pledges, as well as additional units for production redundancy, we aimed to manufacture a total of 4300 Aimicat units. This was how we prepared, and ultimately executed the plan.

We allotted ourselves a month and a half to complete the production of all the devices. This timeline posed considerable challenges for both us and the factory at the time. However, driven by the urgency to get all backers their products as quickly as possible, we were determined to swiftly overcome these obstacles and realize the timely delivery of AIMICAT.

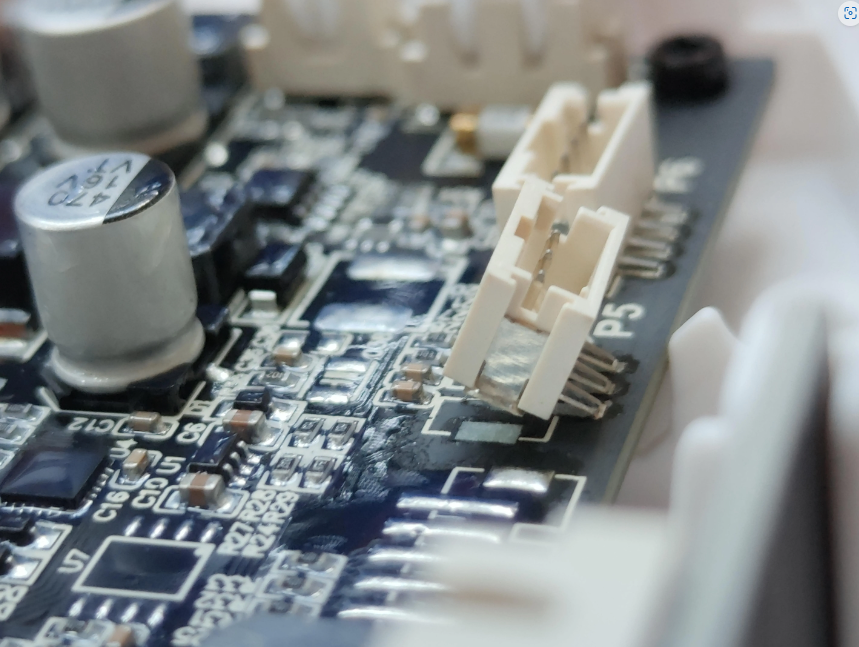

However, this rapid pace also exposed our batch to potential instability, resulting in a range of issues. Yet, these challenges also offered us valuable insights for future iterations. For example, when the subsequent issue of button board malfunctions emerged, we promptly designed new replacement button boards. This allowed users to receive replacements and address the problems. Consequently, we now possess a high level of confidence in the quality control of Aimicat Pro units.

In summary, as we embarked on the production of our second batch of 4300 units, our determination to swiftly address challenges and deliver high-quality products to backers underscored our approach. Despite potential uncertainties, the lessons learned from overcoming these hurdles positioned us well for future iterations, building our confidence in Aimicat Pro's product quality and performance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.